How to Choose a Solar Controller for Utility, C&I, and Off-Grid Systems?

Selecting a solar controller that matches your system’s technical and operational requirements is essential for achieving reliable, efficient performance. Whether you are developing a utility-scale plant, a commercial and industrial (C&I) installation, or an off-grid project, the controller plays a key role in managing energy flows, protecting equipment, and ensuring long-term system stability.

A mismatched controller that does not align with your system specifications can result in premature battery failure, compliance issues, and costly downtime. Therefore, to ensure consistent performance and long-term reliability, each controller must be selected based on a thorough understanding of your plant’s configuration, communication protocols, and operating environment.

The following points highlight what to assess before making your selection.

What are the factors to look at when choosing a solar controller?

1. Electrical & System Compatibility

These parameters ensure the controller matches your plant’s electrical design and power capacity.

- System voltage compatibility: The controller must match the system’s operating voltage (e.g., 12V, 24V, 48V, or higher for C&I/utility systems). Using an incompatible voltage can damage equipment or prevent proper charging.

- Maximum PV input power / PV capacity (kWp): Each controller has a limit on how much solar input it can handle. Exceeding this limit can trip protections, reduce efficiency, or cause overheating. Always ensure the controller’s PV capacity aligns with your array size.

- Charge/Discharge current rating: The controller must handle the maximum charging and discharging current expected in your system. Ratings should include safety margins to prevent overheating and extend device life.

- Battery storage capacity: The controller should be able to manage the energy flow to and from your battery bank. Undersized controllers may not fully charge larger storage systems, while oversized ones add unnecessary costs.

- Battery type compatibility: Different batteries (lead-acid, lithium-ion, LFP, etc.) require different charging algorithms. Choosing a controller that supports your battery chemistry ensures safe, efficient, and long-lasting operation.

2. System Architecture and Integration

Focus on how the controller connects, communicates, and scales within your overall setup.

- Number of devices supported: In multi-device or multi-string setups, controllers need to handle multiple connections reliably. Choosing a controller with sufficient input/output channels ensures seamless operation without bottlenecks.

- Communication protocols & data acquisition: Protocols like Modbus, CAN, or RS485 allow controllers to communicate with other devices or energy management systems (EMS). Data acquisition capabilities (logging, monitoring) are critical for performance analysis and troubleshooting.

- Integration with EMS/SCADA: For advanced projects, controllers need to integrate seamlessly with supervisory systems. This enables coordinated control, remote monitoring, and optimization of complex energy systems.

- Scalability & Future-proofing: Projects often expand over time. Choosing a controller that supports higher voltages, modular configurations, or advanced features prevents costly replacements later.

3. Compliance and Environmental Resilience

Ensuring your controller performs safely and consistently under real-world conditions.

- Environmental conditions: Temperature, humidity, dust, and altitude affect controller performance. Look for models with proper IP ratings, cooling mechanisms, or derating guidelines suitable for the project’s location.

- Safety & Compliance standards: Controllers must comply with local and international standards (e.g., IEC, UL, CE). This ensures safety, regulatory approval, and compatibility with utility/grid requirements.

4. Support, Software, and Reliability

Consider the long-term operational stability and service ecosystem around the product.

- Firmware & Software support: Regular updates improve stability, add features, and patch vulnerabilities. Reliable firmware/software support from the manufacturer ensures long-term system adaptability.

- Manufacturer support & Reliability: Beyond specs, the quality of manufacturer support -technical documentation, training, warranties, and after-sales service – makes a significant difference in project success. Reliable brands reduce the risk of downtime and performance issues.

Each of these considerations plays a critical role in how effectively your system performs in real-world conditions. Balancing compatibility, reliability, and scalability ensures your controller delivers consistent results and adapts to evolving project demands.

By addressing these points early in your design process, you can prevent costly issues later and build a control system that operates efficiently and reliably from day one.

Controller Selection Checklist

✔ Identify your system compatibility

✔ Verify voltage and current compatibility

✔ Confirm communication needs and EMS integration

✔ Choose scalable, field-tested technology

✔ Check for after-sales support and firmware updates

✔ Validate cybersecurity and consistent system reliability

✔ Ensure the controller has the necessary compliance and certifications

Which Elum controller is best for your project?

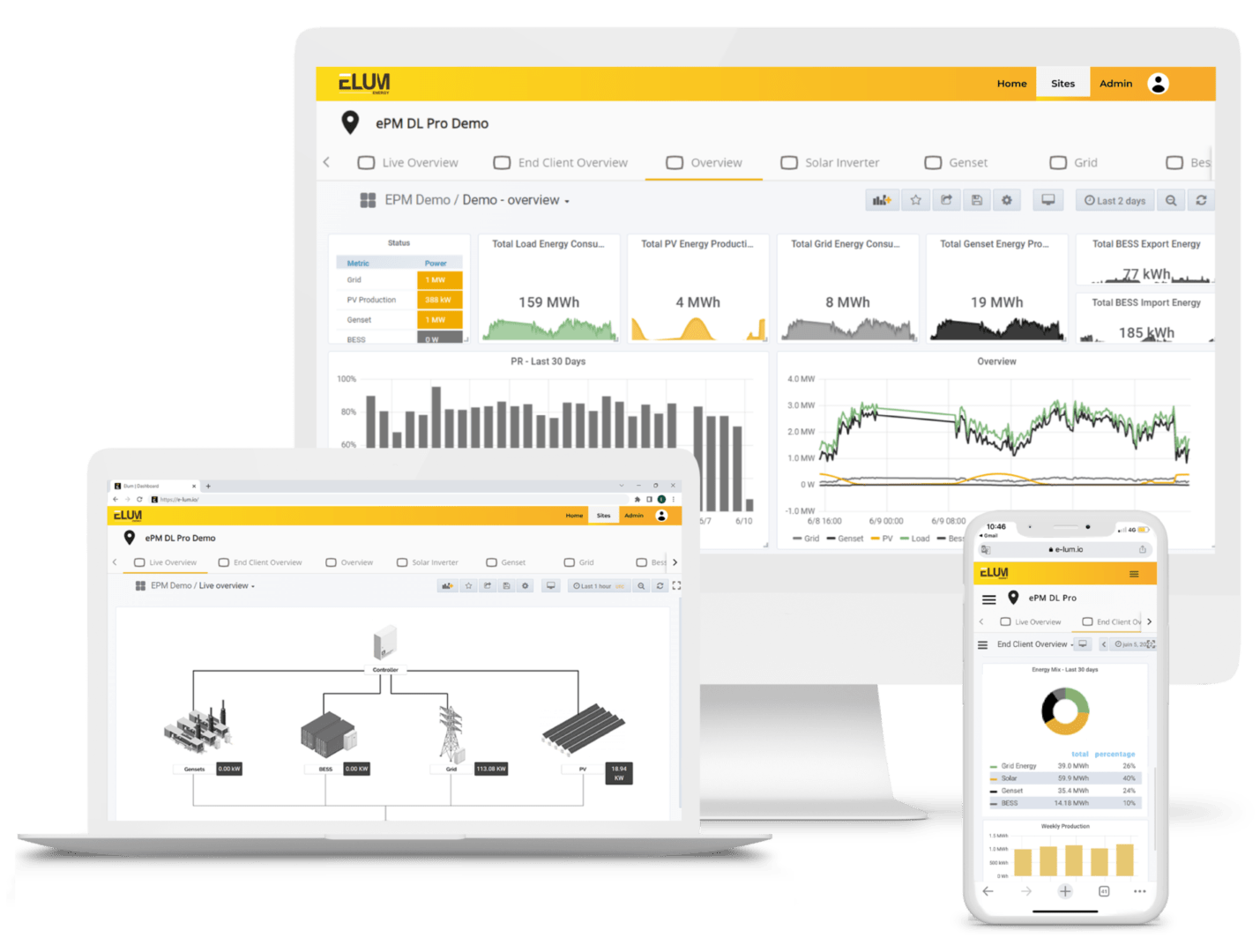

The choice of solar controller plays a critical role in maintaining both the efficiency and reliability of any solar or hybrid system. Elum Energy offers a complete range of ePowerControl solutions designed to meet the needs of every energy application, from off-grid microgrids to large utility-scale plants.

Our portfolio includes controllers tailored for off-grid, hybrid, grid-tied, storage, and EV charging systems, all engineered for seamless integration, grid-code compliance, and long-term reliability.

Working on complex solar projects? Partnering with Elum Certified Installers ensures seamless integration, long-term performance, and compliance with grid codes or advanced EMS/SCADA requirements. Their engineering expertise helps navigate system-level challenges, from sizing and communication to battery and array optimization.

💡 Helpful resources you may find useful:

- A detailed guide on Solar Power ROI with Battery Energy Storage Systems

- Discover how BESS is shaping the next generation of solar energy

Use Case: ePowerControl PPC for 2.2 MWp plant in Somalia

The Laascaanood Plants consist of 4 PV plants, two retrofits and two new, a BESS system and 3 generators.

With ePowerControl PPC, the hybrid plant now:

- Maximizes solar power usage and minimizes fuel dependency

- Integrates new PV capacity safely with existing assets

- Maintains gensets at minimum load for efficient operation

- Achieves greater reliability and overall energy optimization

project with us?