Everything a Solar EPC Should Know About BESS for Power Plants

Introduction

As a solar developer or EPC, increasing solar energy penetration at your power plants is likely a top priority. However, the mismatch between solar production curves and load consumption patterns can make this difficult. One of the most effective and increasingly popular solutions is integrating Battery Energy Storage Systems (BESS) with your solar PV installation.

But when exactly is BESS used in solar power plants and how does it work in practice? In this article, we explore the key benefits of integrating battery storage with solar Energy systems, and how Elum Energy’s Energy Management System (EMS) helps capture this value.

BESS Terms: Definitions and Explanations

- Battery racks: Racks are composed of different cells that convert electrical energy to chemical energy. Different technologies exist (the most popular are Lead-Acid or Lithium-Ion).

- BESS: Battery Energy Storage Systems are composed of PCS and Batteries.

- EMS: An Energy Management System is a controller able to execute a high-level strategy decided by the final user.

- Solar power plants: In this article, the term refers to large-scale solar installations with a capacity greater than 1 MWp. These include supplying electricity to grid-tied systems, powering off-grid cities and remote islands, and feeding isolated industrial sites such as off-grid mines.

Broadly, these installations fall into two categories: grid-tied and off-grid solar power plants.

In grid-tied applications, national Distribution System Operators (DSOs) aim to reduce the intermittency of solar energy production. Batteries can help address this issue by stabilizing energy output and enhancing grid reliability.

In off-grid applications, (e.g. remote cities, islands, or mining operations) electricity is primarily generated by thermal power plants. However, fuel costs are high and volatile due to fluctuations in global oil prices and logistical or security costs.

To reduce this dependence on fossil fuels, energy suppliers are increasingly integrating local energy provisions, such as PV + storage, with their existing diesel gensets. This hybrid approach lowers fuel consumption, enhances energy reliability, and reduces operating costs.

Advantages of Energy Storage Systems for Power Plants

BESS systems, when combined with other power sources, can serves a variety of applications depending on the sizing of PV, Batteries, and Genset but also on the load curve and specific clients requirements.

Within the context of power plants, BESS provides the following features:

- Reliability Increased: Storage can be used for backup purposes. When the grid is down, storage can respond instantaneously and take over supplying energy. This is an essential feature for industries where constant production is crucial as electrical blackouts can damage expensive equipment machines (e.g. mining industry). For this reason, It is important to select a Power Conversion System (PCS) with an uninterruptible power supply (UPS) function for your BESS.

- Reduce Fuel consumption: BESS stores excess solar energy generated during the day and delivers it during peak demand periods which is often during the night in remote cities, villages, and tourist resorts. This means they don’t need to rely on diesel generators to produce power when there is stored energy available. In addition, many countries and remote locations, PV + storage is now more cost-effective than using fuel alone.

- Increase Solar Penetration: When PV production is higher than load consumption, BESS can store the excess production during the day to use it for the other services. Note that the right sizing between PV/Batteries/Gensets is mandatory to maximize your PV penetration.

- Provide behind the meter services: In some countries, utility pricing structures make BESS installations financially attractive:

- Load shifting: When utilities apply time-of-use tariffs (such as peak and off-peak rates), BESS in combination with an Energy Management System (EMS), can charge during low-cost periods and discharge during high-cost periods to reduce energy bills.

- Peak-shaving: For industrial consumers with high demand charges, BESS can discharge strategically during peak usage periods. This helps maintain power consumption below the utility’s maximum demand threshold, avoiding costly peak penalties.

- Provide in front of the meter services: For grid-tied applications, some countries have utility services markets that may allow a BESS to be profitable :

- Utilities can purchase Solar & BESS energy during the evening with a bonus fee. This purchase avoids running peak plants that can be expensive and polluting. This pricing is used, for example, in France in non-connected islands (ZNI) where Solar & BESS systems have been installed during the last years.

- Utilities can pay for frequency regulation services. When the grid’s frequency is low or high, BESS can be discharged or charged accordingly to stabilize the overall frequency of the national grid.

These services can be combined and customized to meet specific client requirements. Implementing an EMS is essential to ensure the project’s profitability, efficiency, and long-term viability.

Characteristics and Limitations of Energy Management Systems

As mentioned above, energy management systems are key to the profitability of a project. It is the central factor that:

- Actively monitors the system’s performance at the device level (PV inverter, Battery PCS, Genset Controllers, Meters, Weather stations, etc.).

- Displays operating information via various interfaces using industrial protocols (Modbus).

- Offers multiple automated modes of operation to meet client requirements.

Different EMS providers exist. Some companies offer Battery Energy Storage Systems with a built-in EMS, while others, like Elum Energy, provide a standalone EMS that is compatible with most leading BESS solutions:

- Compatibility:

Ensuring EMS compatibility with BESS systems, PV inverters, and genset controllers is crucial for the success of any hybrid energy project. In many cases, gensets are existing (brownfield) assets that must be seamlessly integrated into the new system.

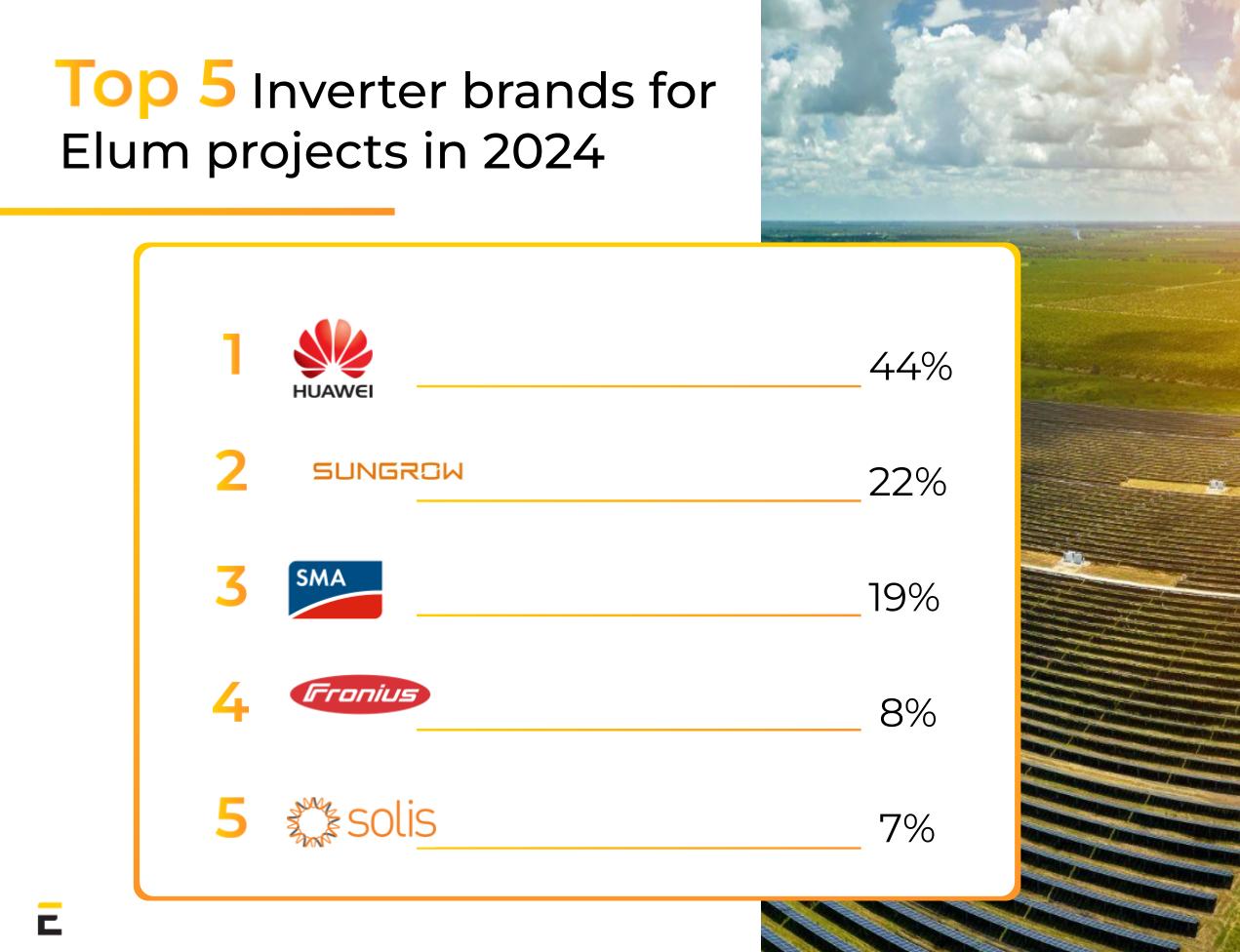

For solar developers and EPCs, having a flexible EMS that supports a wide range of equipment allows for optimal system design. This flexibility enables teams to select the best-performing and most cost-effective PV inverters and battery storage systems based on project-specific requirements such as location, budget, and energy demand.

- Conformity with client requirements:

In sectors like utilities and mining, client requirements often come with strict technical constraints that can make or break a project. Choosing an EMS that can be customized to specific site configurations is a major advantage when bidding for microgrid or hybrid energy projects.

Key considerations include:

1) Control of Relays and Loads: The EMS must be capable of managing breaker operations (opening or closing relays based on the system’s operating mode) to ensure safe and efficient load control.

2) Support for Non-Standard Site Architectures: Many sites have existing (brownfield) electrical infrastructure. The EMS must adapt to these unique configurations, taking into account pre-installed equipment and ensuring full interoperability with legacy systems.

Benefits of ePowerControl Technology for Energy Storage Systems

Solar Controllers - Integration and Management of Power Sources

To improve a solar power plant’s reliability and efficiency, an energy storage controller is essential.

Elum Energy solar controllers connect to PV inverters, battery PCS, and genset controllers to seamlessly integrate and manage multiple power sources.

Utility Scale Power Plant Control and Optimization

Elum Energy’s advanced EMS will automatically control the output power of PV and battery inverters according to client requirements and respect the thermal plant’s constraints.

The PPC controller can manage the spinning reserve and battery sets, manage the reactive active power, and regulate the frequency adapted to the final client needs. Elum is compatible with most of the inverters, PCS, and genset controllers available in the market.

Remote Monitoring & Customizable Alerts

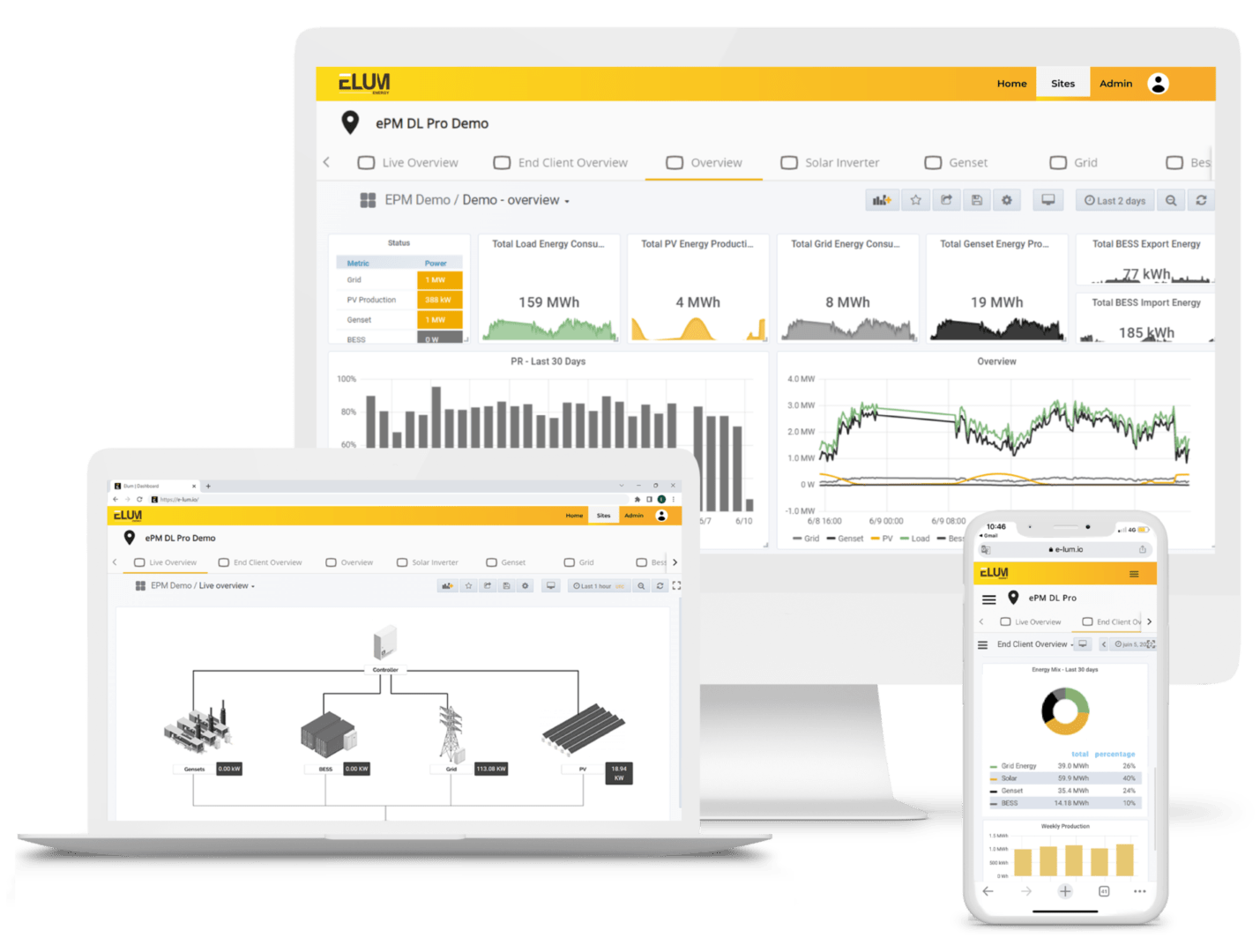

Through a web platform ePowerMonitor, Elum Energy provides remote monitoring.

The interface displays all key performance indicators (KPIs) across various power sources, giving users complete system visibility. The main metrics are outlined below, and you can view the full list further down:

Storage system parameters

Solar system parameters

Genset parameters

- Storage system parameters:

Power output (kW) and energy (kWh)

Frequency

Power factor

Voltage and amperage

Cell temperature

Solar system parameters:

Power output (kW) and energy (kWh)

Frequency

Power

Voltage and amperage

Genset parameters:

Power output (kW) and energy (kWh)

Frequency

Power factor

Voltage and amperage

Fuel level

Running time

Resource: Learn More About BESS

Battery Energy Storage Systems (BESS), when integrated with a smart Energy Management System like the ePowerControl range, offer significant value across both grid-tied and off-grid power applications. From improving reliability and reducing fuel consumption to enabling load shifting and peak shaving, the benefits are both technical and financial.

For those looking to explore these systems in greater depth, you can deep dive into our Ultimate Guide to Battery Energy Storage Systems, a comprehensive resource for solar professionals looking to stay ahead in a rapidly evolving energy landscape.

the solar industry?